Experience, Innovation, and Reliability Since 1971

Welcome to Fiminox, a leader in the distribution of stainless steel components. For over 50 years, we’ve been offering a comprehensive range of screws, bolts, nuts, washers, threaded rods, pipes, fittings, and valves, designed for high performance and long-lasting durability. Discover how our products meet the specific needs of your industry.

Products

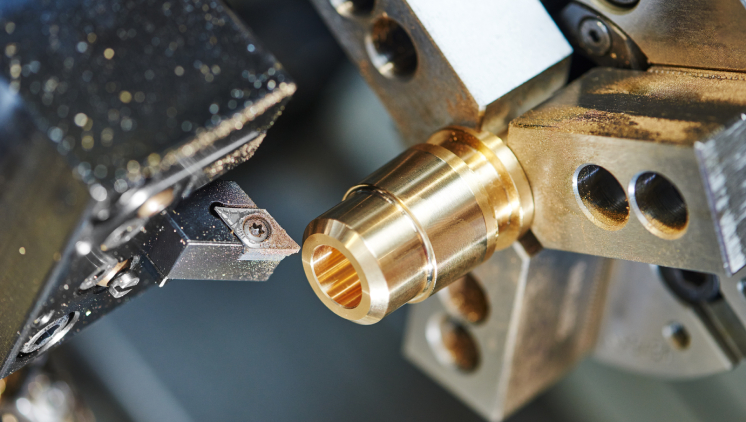

Fiminox specializes in the distribution of stainless steel fasteners, both standard and custom, as well as turned metal parts, providing high-quality fastening solutions in stainless steel. Thanks to our expertise and flexibility, we can deliver both standard products and custom-made solutions tailored to the specific requirements of our clients.

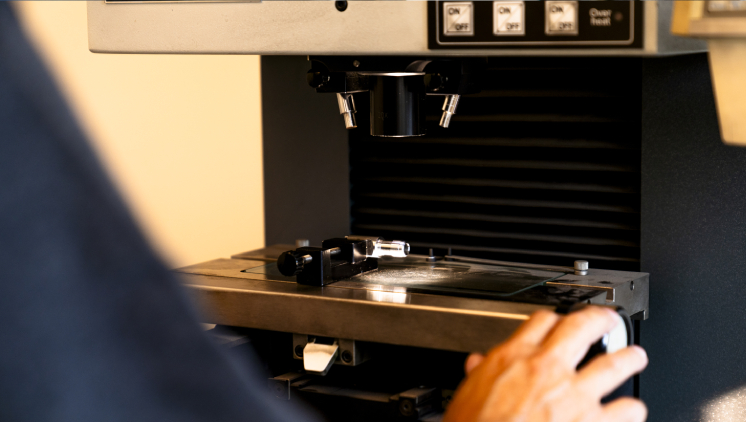

Services

Fiminox provides a comprehensive service package, including technical consultancy, customization, and post-sales support to assist you at every stage of your project.

Application Sectors

Our products are designed to meet the needs of various industries, including food, pharmaceutical, chemical, and energy.

Learn how Fiminox can make a difference in your sector.

Certified Quality

Materials compliant with international standards and rigorous quality control.

Experience and Reliability

Over 50 years in the industry, synonymous with expertise and professionalism.

Continuous Innovation

Constantly investing in new technologies to provide cutting-edge products.

Comprehensive Support

Technical assistance and consultancy for every need.